Training Workshops

The purpose of our Training Workshops is to train end-users academically about all the unique advantages and disadvantages of each specific electrochlorination technology available on the international market. Selecting the correct electrochlorination technology and ELECTROLYZER type for a specific application can become a very complex matter and can result in very expensive mistakes. Fortunately end-users can rely on Chlor Generators for all the necessary assistance.

Typical topics covered in our training Workshops

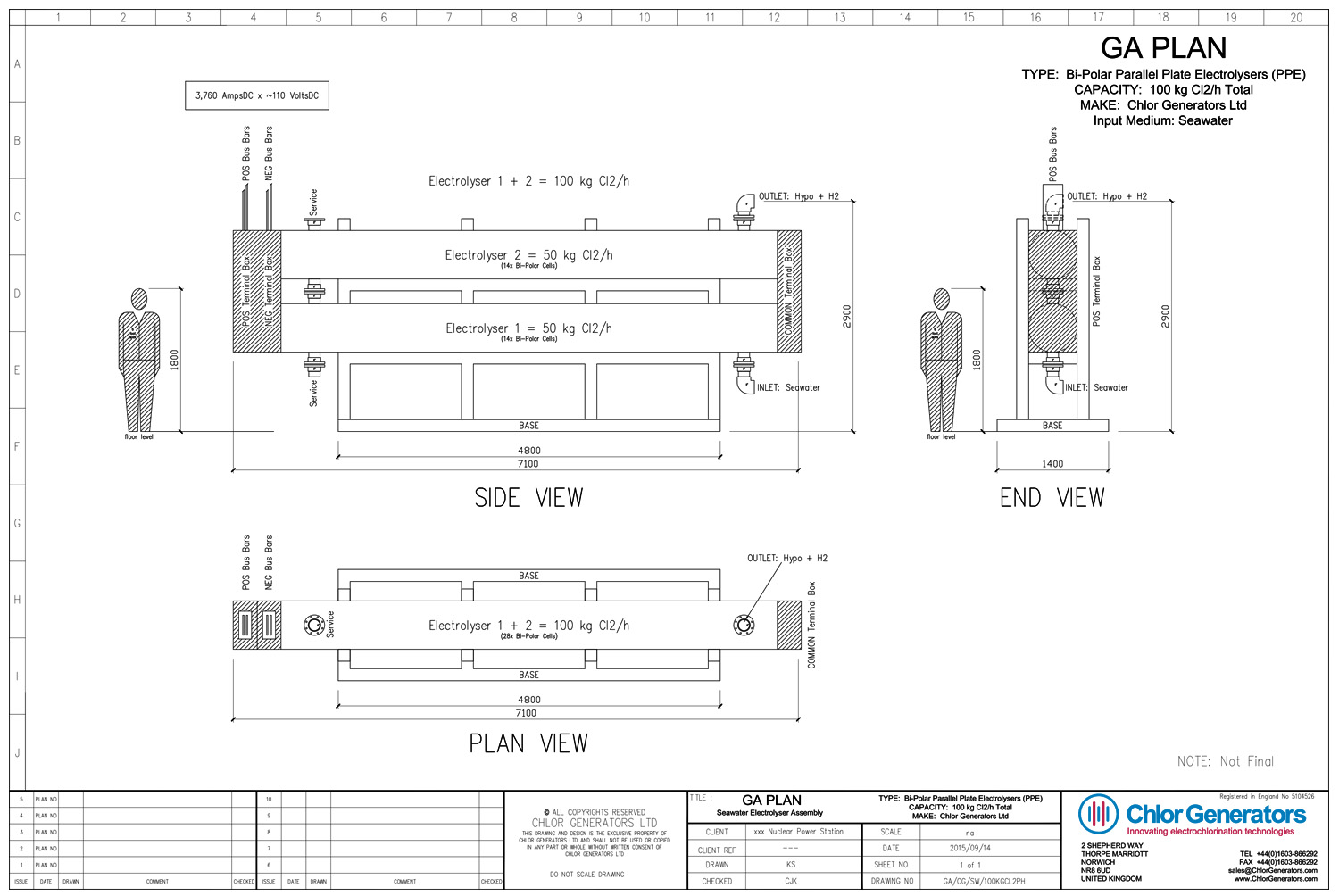

- the main differences between plate and tubular ELECTROLYZERS.

- the preferred applications for plate ELECTROLYZERS versus tubular ELECTROLYZERS.

- the main differences between monopolar and bipolar ELECTROLYZERS.

- the importance of “optimum” balance” between AmpsDC and VoltsDC for ELECTROLYZERS.

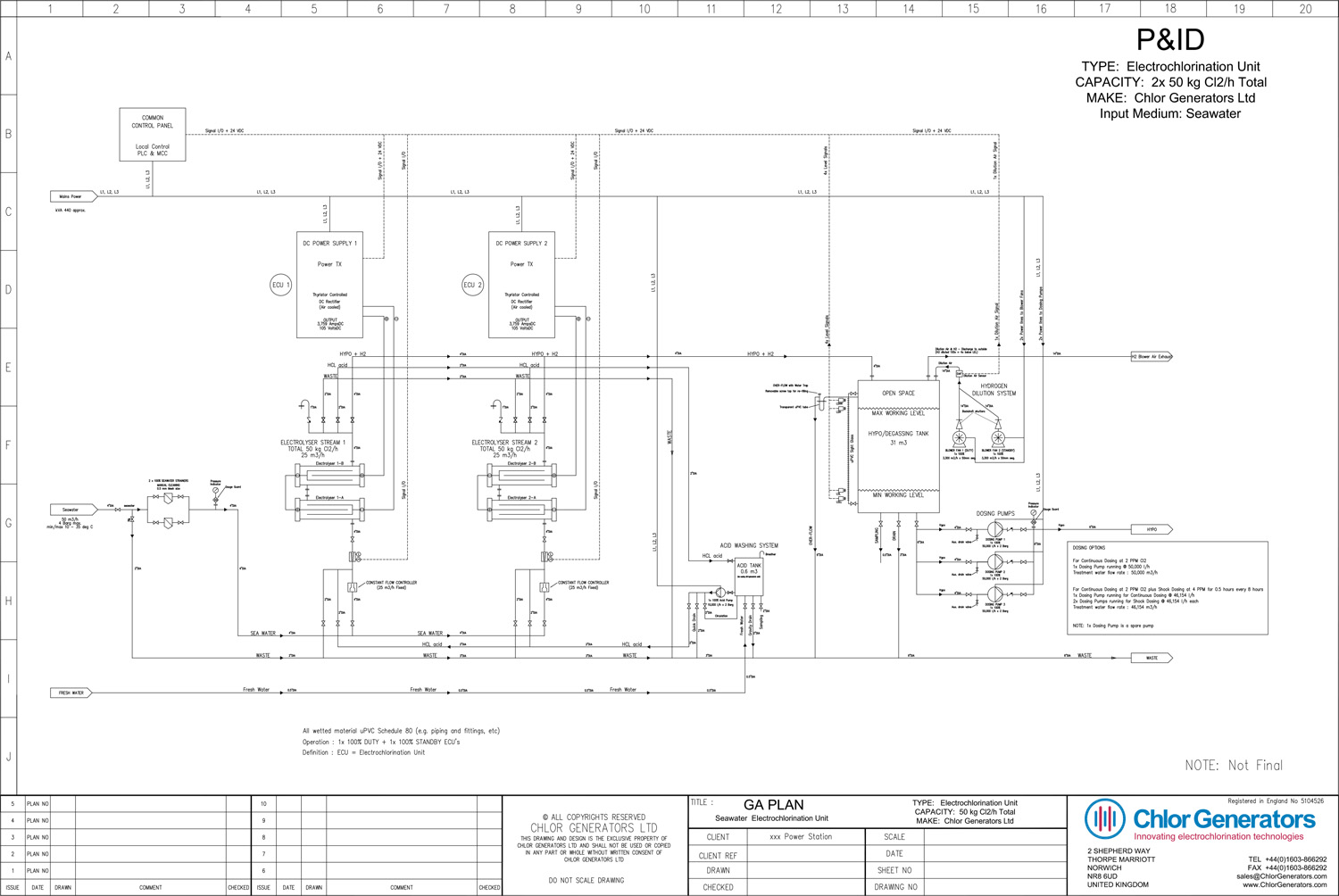

- how to determine the actual kg Cl2/h output of an electrochlorination system.

- how to determine the Cl2 concentration of HYPO.

- how to determine when acid washing is required.

- which acid washing method and procedure is the best.

- the main differences between Continuous and Shock dosing.

- how to calculate the volume of a hypo storage tank in case of Shock dosing.

- how does higher or lower HYPO concentrations impacts the same electrochlorination system.

- what is the max allowable HYPO concentration for tubular ELECTROLYZERS and what are the consequences thereof.

- the main differences between conventional and ChlorGen Safety Threetube tubular ELECTROLYZERS.

- the inherent design flaws of vertically mounted plate ELECTROLYZERS compared to horizontally mounted ones.

- design options for ballast water treatment ELECTROLYZERS.

IMPORTANT: It is recommended that end-users first complete one of our Training Workshops before considering any engineering work on their electrochlorination systems. We also offer Technical Consultancy services for such engineering work. For more information, click Technical Consultancy

Our team at Chlor Generators is looking forward to hearing from end-users who are interested in our Training Workshops.

Contact Us

Tel: +44 (0)1603 260663

email: sales@chlorgenerators.com

Chlor Generators (UK) Ltd

Unit 10 Delta Close

Norwich

NR6 6BQ, United Kingdom

Copyright Chlor Generators Ltd. 2021 / All Rights Reserved